The transmission is the core component of a vehicle's drivetrain system, and the efficient and reliable operation of its control system is crucial for enhancing vehicle performance and safety.

VCARSYSTEM's self-developed Hardware-in-the-Loop (HIL) testing system for transmissions simulates the operation of real vehicles under various operating conditions. This effectively validates the reliability of the TCU, ensuring its stability and safety on actual roads. The system can simulate various faults and abnormal conditions to test the system's fault tolerance, significantly reducing the number of tests required on actual vehicles. This helps users detect and resolve issues early in the development stages, thus reducing development time and costs effectively.

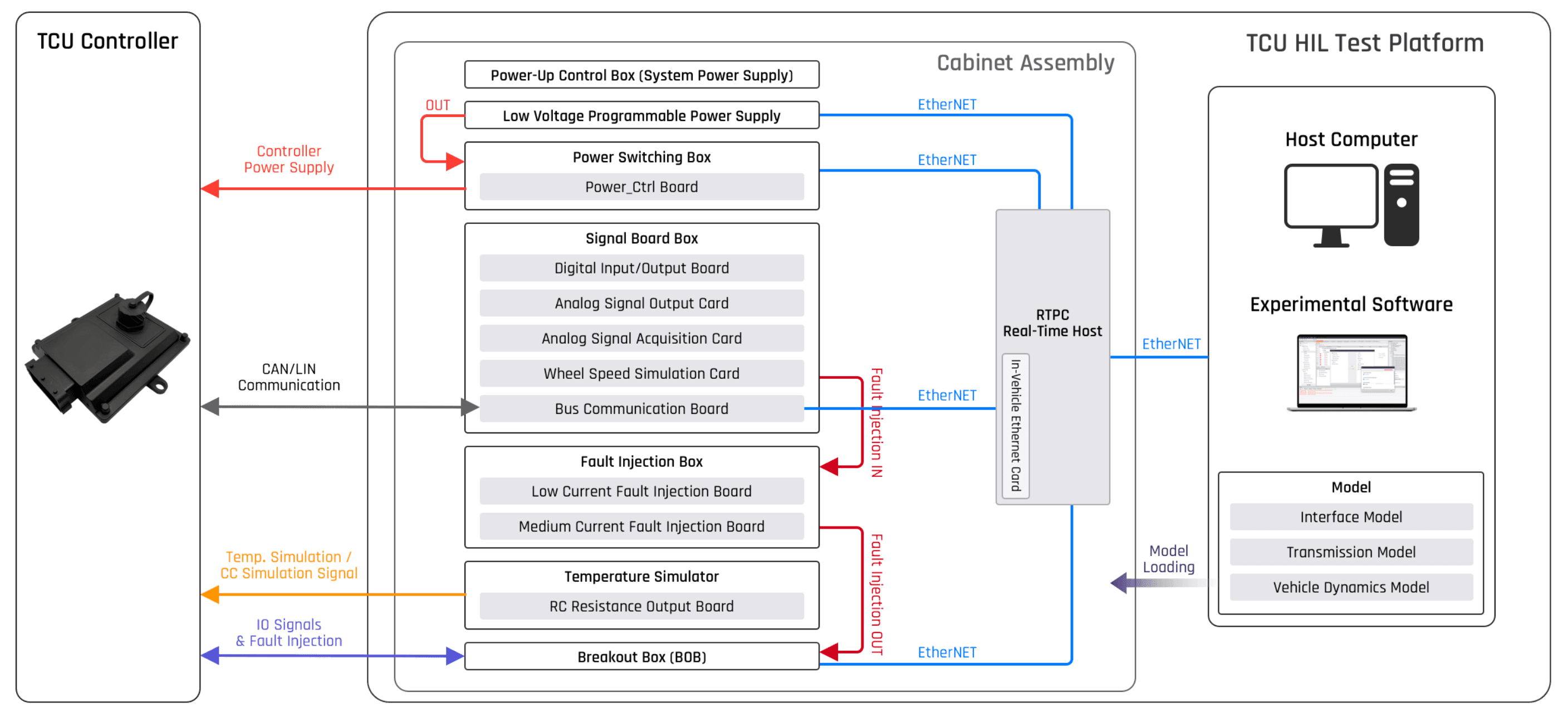

The VCARSYSTEM's self-developed TCU HIL testing platform consists of software on host PC and a cabinet. It uses hardware boards to simulate or collect hardwired and bus signals required by the TCU, achieving functional and logical validation of TCU.

Independent Developed Multi-functional Board System: Independent developed various types of modules, including DIO modules supporting basic digital and PWM signal input/output functionalities, and CAN communication modules supporting CAN, LIN, and FlexRay protocols with abundant channel resources.

High Integration and Portability: High integration, easy to move and use.

Resource Expansion & Multi-Cabinet Integration: Supports resource pooling, multiple users accessing devices simultaneously, suitable for various application scenarios.

Software development and configuration capabilities: Host computer engineering configuration software, experiment management software, and automated testing software do not require a license.

Automated configuration of hardware board signals, bus signals, and mapping relationships between input/output interface models.

Supports importing and hierarchical viewing of Simulink physical models without additional Simulink licenses.

Provides rich optional configurations, meets customized requirements, short procurement cycles.

Fault Injection、Measurement and Calibration: Fault injection implemented through modules functionality, no additional software required.

Provides measurement calibration libraries, no need for ICA, CANAPE calibration and diagnostic software.

Development and Model Support: No license required, supports customer secondary development, multiple computers can simultaneously use physical models.

Supports M-script for automatic generation of communication interface modules for dbc/ldf files and hardware interface definition files, with Override functionality.