Power batteries are the core energy source of (new energy vehicles)NEVs, and the Battery Management System (BMS) is crucial for connecting the battery pack with the vehicle's overall system. To ensure the performance and reliability of the BMS, HIL (Hardware-in-the-Loop) simulation testing is crucial in the development of new energy vehicles.

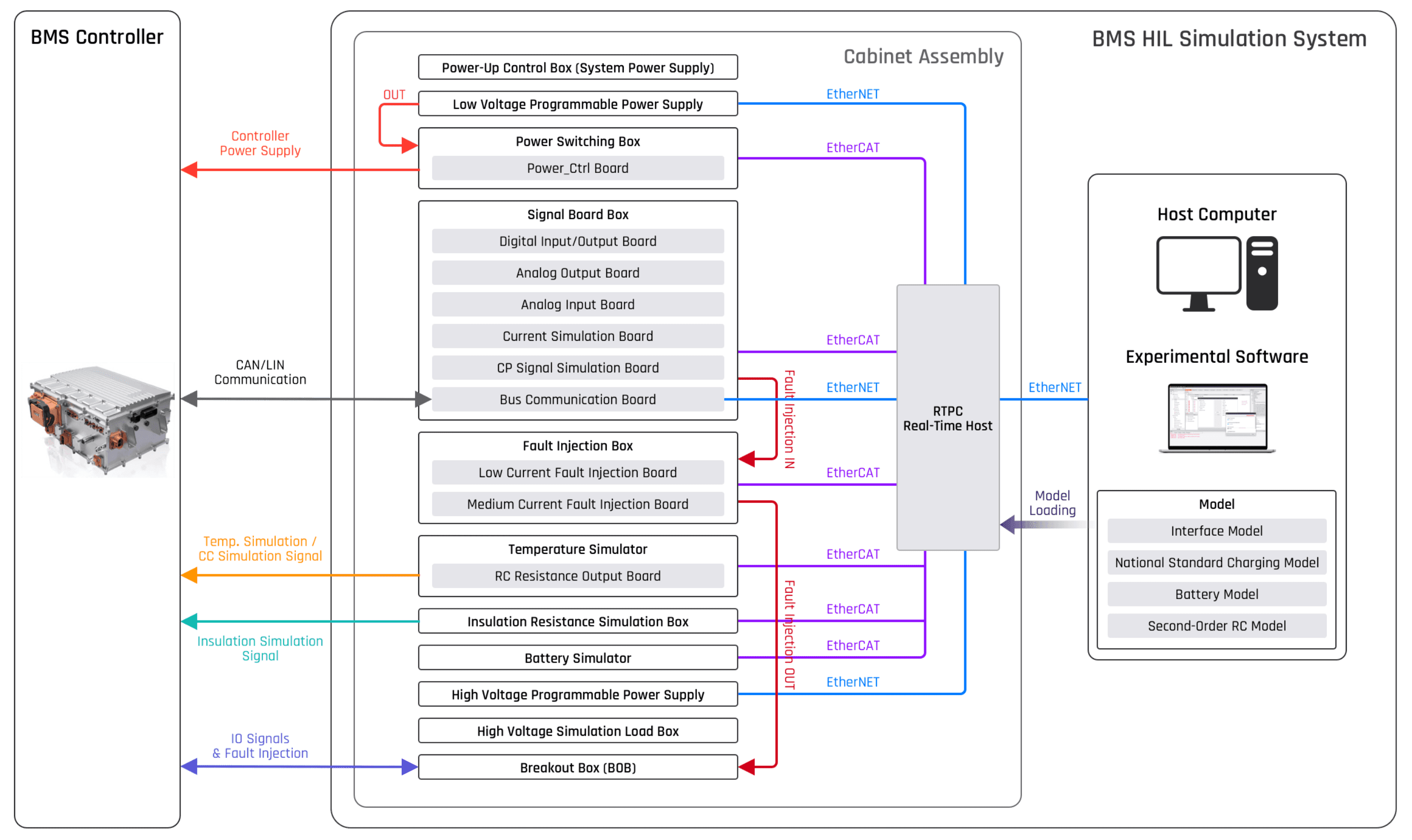

VCARSYSTEM has independently developed a BMS HIL (Hardware-in-the-Loop) simulation system, specifically designed for the automated testing of BMS controllers. In a laboratory environment, this system can efficiently and accurately verify the control logic and functional responses of the controller during the R&D phase. By precisely simulating the input signals required by the controller and monitoring its output signals in real time, it comprehensively tests the controller's functional logic, communication capabilities, and fault diagnosis functions, ensuring the stability and reliability of the controller in practical applications, and greatly improving the efficiency of controller development and debugging.

Independent R&D and Diversified Features:

All types of boards are independently developed, covering functionalities such as DIO and CAN communication, meeting diverse needs for signal acquisition/output.

High Integration and Portability:

The system features high integration, making it easy to transport and use across various testing environments.

Scalability and Resource Pooling:

Resources are scalable, supporting multi-cabinet linkage to accommodate a wider range of applications.

Resource pooling allows simultaneous access for multiple users, facilitating wireless remote operation for engineers.

Customization and Flexibility:

Rich optional configurations enable high cost-effectiveness and short procurement cycles, meeting diverse customization needs.

Supports Simulink physical model import and hierarchical viewing without additional licensing.

Fault Injection, Measurement and Calibration:

Convenient fault injection functionality is available without additional software.

Measurement and calibration libraries are provided for controller measurement,calibration and diagnostics, eliminating the need to purchase additional calibration and diagnostic software.

Model Development and Usage:

No additional licensing required; customers can develop models and use physical models simultaneously on multiple computers.

Models encompass interfaces, drivers, virtual controllers, and vehicle models including engines, motors, transmissions, batteries, and vehicle dynamics.

Automatic Generation of IO Interfaces:

Communication interface modules for dbc/ldf files and hardwired interface definition files are automatically generated using m-script. Override functionality is supported to enhance the convenience of communication configuration.