Motor control development involves high voltage, high current, and direct motor bench testing carries significant risks, requiring a high level of algorithm maturity. In order to reduce development risks and improve testing efficiency, the MCU HiL simulation testing solution provided by VCARSYSTEM offers strong support for MCU development.

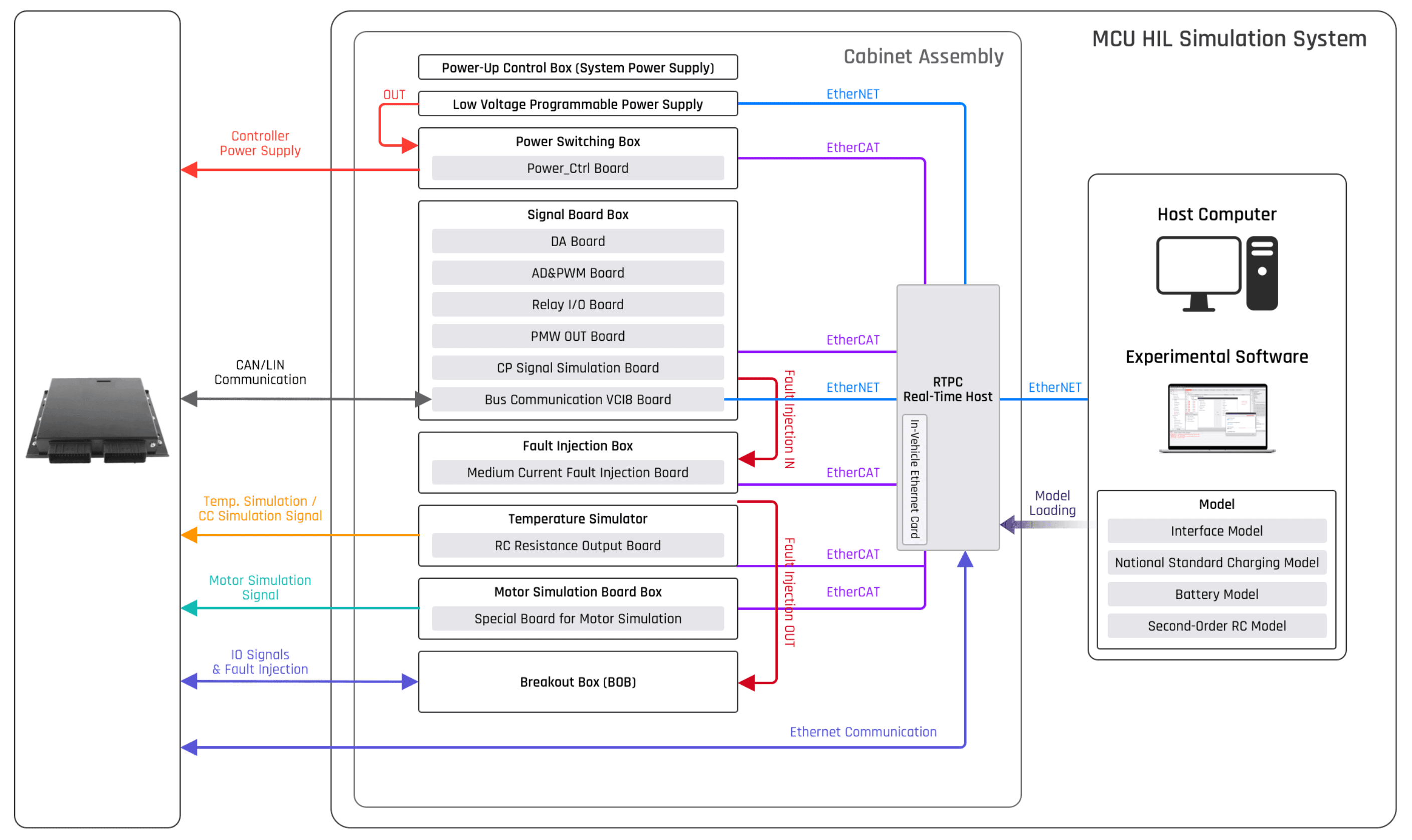

The MCU HIL simulation test system comprises core components such as real-time PC, FPGA motor simulation modules, and CAN communication modules and etc. Motor modules are downloaded to the FPGA via the host computer to enable direct data output. The system supports closed-loop control, facilitates data interaction via CAN modules, and utilizes experiment management and automation software for testing, fault injection, and test case editing, comprehensively validating MCU performance.

In-house Developed Multi-functional Board Cards:

Various modules independently developed, including Voltage/PWM signal input boards and CAN communication boards.

Multi-type Signal Acquisition Capability:

Voltage/PWM signal input boards integrate voltage, digital, and PWM signal acquisition capabilities.

Single board supports multiple signal acquisition types, cost-effective.

CAN Communication Boards Supporting Multiple Protocols:

CAN communication boards support CAN, LIN, and FlexRay protocols.

Provide abundant channel resources to meet complex communication needs.

High Integration and Portability:

Designed with high integration for easy mobility.

Lightweight design suitable for various applications including automotive environments.

Rich Optional Configurations and Customization Support:

Offer diverse optional configurations to support customization needs.

Shorten procurement cycles to meet various testing requirements.

Software Support and Automation Features:

Upper-level software engineering configuration, experiment management, and automated testing software can be shared by multiple users with a single license.

Support Simulink physical model import and hierarchical viewing without additional Simulink license.

Fault Injection, Measurement and Calibration:

Support fault injection functionality without additional software.

Provide measurement calibration library without the need for INCA, CANAPE calibration and diagnostic software.

Physical Model Development and Usage:

No license required, support customer secondary development, simultaneous use of physical models on multiple computers.

Models include IO interface, driver, virtual controller, and vehicle models, covering components such as engine, motor, TCU, battery, and vehicle dynamics.

Automatic Generation of IO Interfaces:

Support automated generation of communication interface modules for dbc/ldf files and hardwired interface definition files via m-script.

Provide Override functionality to enhance flexibility and convenience in communication configuration.